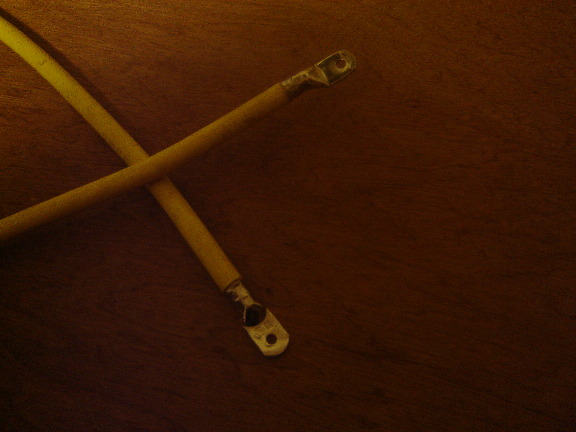

Mostly as a test, I made up a short cable, crimping the nickel-plated cable lugs on the ends of the cable. The crimper works great!

Here's the motor, adapter plate, clutch, et cetera mated-up to the transmission.

Another view.

Seperated them again so you can see the clutch

and the input shaft of the transmission.

Measuring runout of the flywheel.

Decided to remove the ring gear that the starter motor engaged with. Used a cutoff wheel on my Dremel to nibble most of the way through the ring. Thought I'd hit it with a chisel when it was nearly through, but that turned out to be unnecessary -- the ring gear is a shrink fit on the flywheel body, which creates a tremendous amount of stress. It made a satisfying little "ting" when I was most of the way through and suddenly the ring was loose.