This morning the lovely lady seen in yesterday's final image reminded me that I had a teeth cleaning appointment at 1:00. Grrrr... it seems like "life" is constantly interfering with the EV project.

I did get a little done before the appointment (my teeth are doing fine, by the way) but afterwards I was volunteered for a job procuring a stove and installing it in a third floor apartment. So, the amount of productive EV labor was minimal.

The job I started on is something that wouldn't normally be necessary, as batteries normally have some number of cells prepackaged together. One of the advantages of the BB600 cells I'm using is that they are CELLS not BATTERIES. The word "battery" is a collective noun -- like a flock of seagulls, or a school of fish, or a parliament of owls -- when you put a bunch of cells together they form a battery. The familiar batteries that go in flashlights and other electronics are usually not, in fact, batteries -- they're cells. So one should say "D cell" not "D size battery" the one exception in the traditional battery world are the small 9 volt rectangular batteries that have snap-on terminals and usually go in smoke detectors -- they are truly batteries, if you tear one apart you'll find 6 tiny cells inside.

Since my cells are individually packaged, if one goes bad I just have to replace that one, not it and all its mates in a battery. That's a nice advantage. On the other hand it's convenient to be able to lug a few around at a time, so I'm packaging them up into little 12 volt assemblies -- batteries with 10 cells each. These cells also need to be physically restrained or they will blow up like balloons during charging; these 10 cell carriers will take care of that issue too. I had ordered some aluminum, flat stock and angle, from Online Metals for this purpose. Subsequently, I've found out that aluminum is one of the worst possible choices electrochemically; aluminum and nickel are far apart in the galvanic series so in the presence of an electrolyte (and there will be some stray KOH in my battery boxes) the aluminum will be eaten away and plated onto the nickel parts. I'm going to use several coats of epoxy paint and pray for the best.

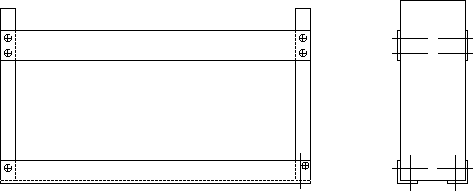

The containers I'm making for the cells will look like this:

The blocks at the end are wood and the only thing that got accomplished today was that I got some of them cut out. I bought some nice poplar 1 by 4's yesterday (yet another trip to Home Depot -- one where I made the fateful observation that they had a pretty nice Maytag stove on clearance -- a floor model).

First I ripped them all down to a width of 3.16, then started using the chop saw to get the 8.62 height I need. There will be 20 of these carriers so that's 40 of the end blocks.

I've finished with this many:

And I have this many to go:

Tomorrow is the NEEAA meeting at Bob Rice's house in Killingsworth. I really should work on the cell carriers but I'm going to go to the meeting anyway. I want to see if anyone wants to try out my ersatz car weighing equipment...