Today was pretty hot. Felt like high 90's to me but the weather.com site tells me the high was only 88. My plan was to throw together my leverage based gizmo for car weighing in the morning and head up to the garage in the afternoon. Well, I was still working on the lever at dinnertime! Must have been the heat. Probably the weather channel is in colusion with the government to hide the true extent of this global warming thing.

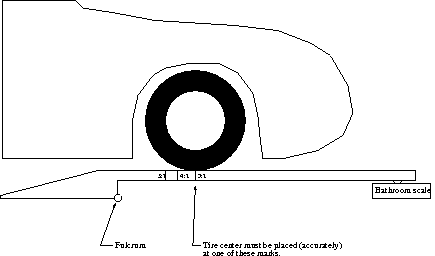

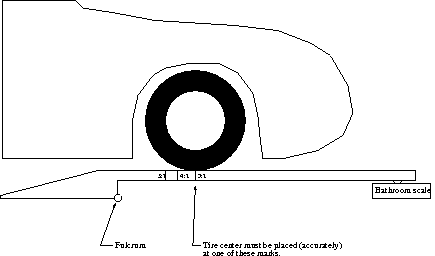

My plan was to make an integrated ramp and lever assembly. You drive the car up into position on the ramp and its weight is transmitted (reduced by the mechanical advantage of the lever) to an ordinary bathroom scale.

I believe this will be much more accurate than weighing the car on a big scale like one might find at a dump or a gravel quarry. On the other hand, it is a bit more work as you have to weigh each wheel individually. On the other other hand, by weighing each corner of the car individually I get information about the location of the car's center of gravity. I know the converted car will be heavier, but I want its CG to be in the same place -- AND I want the polar moment of inertia kept low.

Here's the finished lever arm (it's laying on its side for better visibility).

A little bit closer.

Close-up of the fulcrum region.

It's 72 inches from the fulcrum to the pad that pushes on the bathroom scale. If the wheel's center is 24 inches from the fulcrum we get a 3 to 1 mechanical advantage -- if it's 18 inches the mechanical reduction is 4 to 1. Not shown is a mark at 12 inches that gives a 6 to 1 reduction. If you use the 6:1 location and the scale reads 200 pounds, you have 1200 pounds on that wheel. The back wheels of Dave Oliveria's truck are probably right around that!

Phase one complete. Now I have to make a ramp-only deal for the other wheel.